The pro-cut rotor matching certification answers provide a comprehensive guide to the principles and practices of rotor matching. This certification ensures that technicians have the knowledge and skills to perform rotor matching accurately and efficiently, ensuring optimal performance and longevity of rotating equipment.

The guide covers the basics of rotor matching, including the purpose and benefits of certification, different types of certifications available, and a step-by-step guide to obtaining certification. It also delves into the process and techniques of rotor matching, emphasizing the importance of precision and accuracy.

Additionally, the guide discusses industry standards and specifications for rotor matching, highlighting the role of organizations like ANSI and SAE in setting these standards.

Pro-Cut Rotor Matching Certification Basics: Pro-cut Rotor Matching Certification Answers

Pro-cut rotor matching certification is a specialized credential that demonstrates an individual’s proficiency in matching and assembling rotors to precise specifications. This certification is essential for technicians who work on high-performance engines and other applications where precision and accuracy are critical.

Benefits of Pro-Cut Rotor Matching Certification

- Enhanced job opportunities

- Increased earning potential

- Improved customer satisfaction

- Reduced downtime and maintenance costs

- Enhanced safety and reliability

Types of Pro-Cut Rotor Matching Certifications

There are various types of pro-cut rotor matching certifications available, each with its own specific requirements and focus. Some common certifications include:

- Automotive Service Excellence (ASE) Pro-Cut Rotor Matching Certification

- National Institute for Automotive Service Excellence (ASE) Pro-Cut Rotor Matching Certification

- Society of Automotive Engineers (SAE) Rotor Matching Certification

Step-by-Step Guide to Obtaining Pro-Cut Rotor Matching Certification

- Meet the eligibility requirements for the specific certification you are seeking.

- Enroll in a training program that covers the necessary skills and knowledge.

- Practice and develop your skills through hands-on experience.

- Take and pass the certification examination.

- Maintain your certification by completing continuing education and recertification requirements.

Rotor Matching Process and Techniques

Process of Rotor Matching

Rotor matching is a precise process that involves matching the weight, balance, and runout of two or more rotors to ensure optimal performance. The process typically includes the following steps:

- Cleaning and inspecting the rotors

- Measuring the weight and balance of each rotor

- Matching the rotors to within specified tolerances

- Assembling the rotors with the correct torque and preload

Techniques for Rotor Matching

There are two primary techniques used for rotor matching: bore matching and journal matching. Bore matching involves matching the diameter and surface finish of the rotor bore to the shaft or journal. Journal matching involves matching the diameter and surface finish of the rotor journal to the bearing or housing.

Importance of Precision and Accuracy in Rotor Matching

Precision and accuracy are essential in rotor matching. Mismatched rotors can lead to excessive vibration, noise, and premature failure. Proper rotor matching ensures smooth operation, reduced wear and tear, and extended component life.

Rotor Matching Standards and Specifications

Industry Standards and Specifications

The rotor matching industry is governed by a number of standards and specifications. These standards provide guidelines for the design, manufacturing, and testing of rotors and related components. Some of the most important standards include:

- American National Standards Institute (ANSI) B5.26

- Society of Automotive Engineers (SAE) J1349

- International Organization for Standardization (ISO) 1940

Role of Organizations in Setting Standards

Organizations such as ANSI, SAE, and ISO play a vital role in setting standards for rotor matching. These organizations bring together industry experts to develop and maintain standards that ensure the quality and safety of rotor matching practices.

Consequences of Not Adhering to Rotor Matching Standards

Failure to adhere to rotor matching standards can have serious consequences, including:

- Increased vibration and noise

- Reduced performance and efficiency

- Premature failure of rotors and related components

- Safety hazards

Best Practices for Pro-Cut Rotor Matching

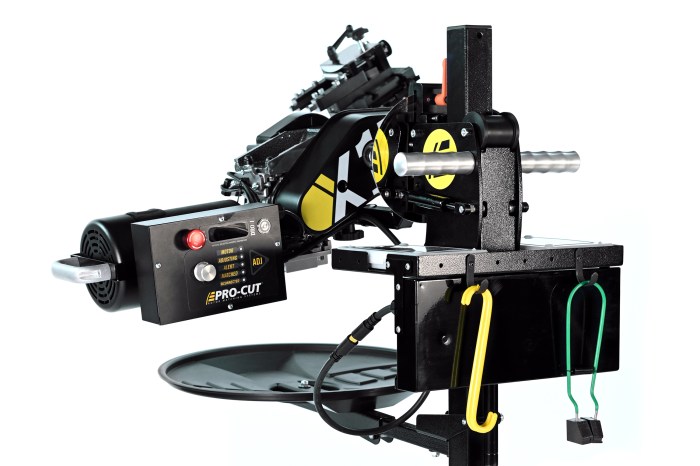

Proper Equipment Maintenance and Calibration, Pro-cut rotor matching certification answers

Proper equipment maintenance and calibration are essential for accurate rotor matching. This includes regularly cleaning and inspecting equipment, calibrating measuring devices, and following manufacturer’s recommendations for maintenance and repair.

High-Quality Rotors and Components

Using high-quality rotors and components is crucial for successful rotor matching. Rotors and components should be manufactured to precise tolerances and meet industry standards.

Role of Training and Experience

Training and experience are essential for ensuring successful rotor matching. Technicians should receive formal training from qualified instructors and gain practical experience under the supervision of experienced professionals.

Troubleshooting Rotor Matching Issues

Common Rotor Matching Issues

Common rotor matching issues include:

- Excessive vibration

- Noise

- Premature failure

- Runout

Causes of Rotor Matching Issues

The causes of rotor matching issues can vary depending on the specific problem. Some common causes include:

- Mismatched rotors

- Improper assembly

- Damaged or worn components

- Improper lubrication

Troubleshooting Tips

Troubleshooting rotor matching issues involves identifying the cause of the problem and taking corrective action. Some common troubleshooting tips include:

- Inspecting the rotors for damage or wear

- Verifying that the rotors are properly matched and assembled

- Checking the lubrication of the components

- Consulting with a qualified technician or engineer

Rotor Matching Certification Examination

Format and Content of the Examination

The pro-cut rotor matching certification examination typically consists of a written test and a practical skills assessment. The written test covers the theoretical knowledge and principles of rotor matching, while the practical skills assessment evaluates the candidate’s ability to perform rotor matching tasks.

Eligibility Requirements

Eligibility requirements for the rotor matching certification examination vary depending on the specific certification being sought. Generally, candidates must have a high school diploma or equivalent and some experience in the field of rotor matching.

Tips for Preparing for and Passing the Certification Examination

To prepare for and pass the rotor matching certification examination, candidates should:

- Study the relevant materials thoroughly

- Practice rotor matching tasks under the supervision of a qualified instructor

- Take practice tests to familiarize themselves with the format and content of the examination

- Get a good night’s sleep before the examination

Question Bank

What is the purpose of pro-cut rotor matching certification?

Pro-cut rotor matching certification ensures that technicians have the knowledge and skills to perform rotor matching accurately and efficiently, ensuring optimal performance and longevity of rotating equipment.

What are the different types of pro-cut rotor matching certifications available?

There are various types of pro-cut rotor matching certifications available, each with specific requirements and focus areas. Some common certifications include those offered by the American National Standards Institute (ANSI), the Society of Automotive Engineers (SAE), and equipment manufacturers.

What is the step-by-step guide to obtaining pro-cut rotor matching certification?

The step-by-step guide to obtaining pro-cut rotor matching certification typically involves meeting eligibility requirements, completing training programs, and passing a certification examination. The specific requirements may vary depending on the certification body.